Bespoke Design / Hybrid Cables

Offering tailored solutions that exceed expectations and deliver superior results in even the most challenging environments.

Cable Solutions Worldwide, design, manufacture and test bespoke electrical, optical and hybrid composite subsea cables, including tethers and underwater umbilicals for unique and challenging onshore and offshore applications. We work in four key markets, oil & gas, subsea, marine & shipbuilding and renewables, focusing on bespoke cable technology and innovation for subsea and topside applications.

With a strong emphasis on innovation and quality, the company’s in-house design department has developed a diverse portfolio of bespoke cable designs tailored to meet the unique requirements of clients operating in challenging environments.

Our in-house cable design team is respected worldwide for its high level of energy industry knowledge and innovation, achieving unique cable design solutions for many bespoke subsea and topside applications.

Our cables are tested extensively for performance and endurance, both internally and externally by third party verification companies. Importantly, our bespoke hybrid cables have a proven track record over many years on oil & gas, subsea, marine & shipbuilding and renewable energy projects.

Of particular note is Cable Solutions’ ability to offer bespoke cable design solutions, providing clients with unique cable lengths for project trials and customisation needs. This flexibility, accompanied by a strong focus on customer care, has established the company as a dependable and innovative partner in the cable industry.

A key aspect of Cable Solutions’ approach is its commitment to close collaboration with clients, enabling a deep understanding of the challenges posed by harsh environments. By meticulously assessing environmental constraints and performance requirements, the company develops cable designs that not only meet but exceed expectations, ensuring exceptional performance under demanding conditions.

With its unwavering commitment to excellence, innovation, and customer satisfaction, Cable Solutions Worldwide continues to lead the way in bespoke cable design, offering tailored solutions that exceed expectations and deliver superior results in even the most challenging environments.

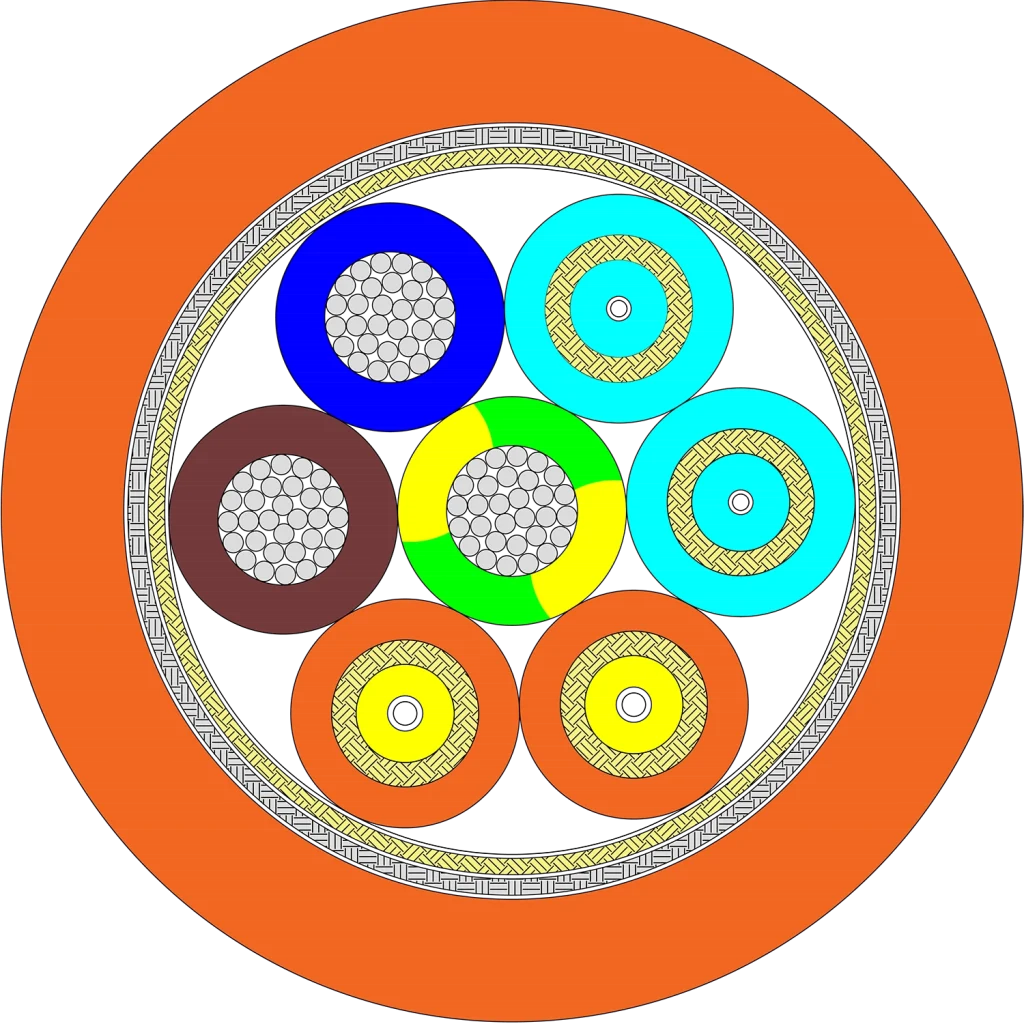

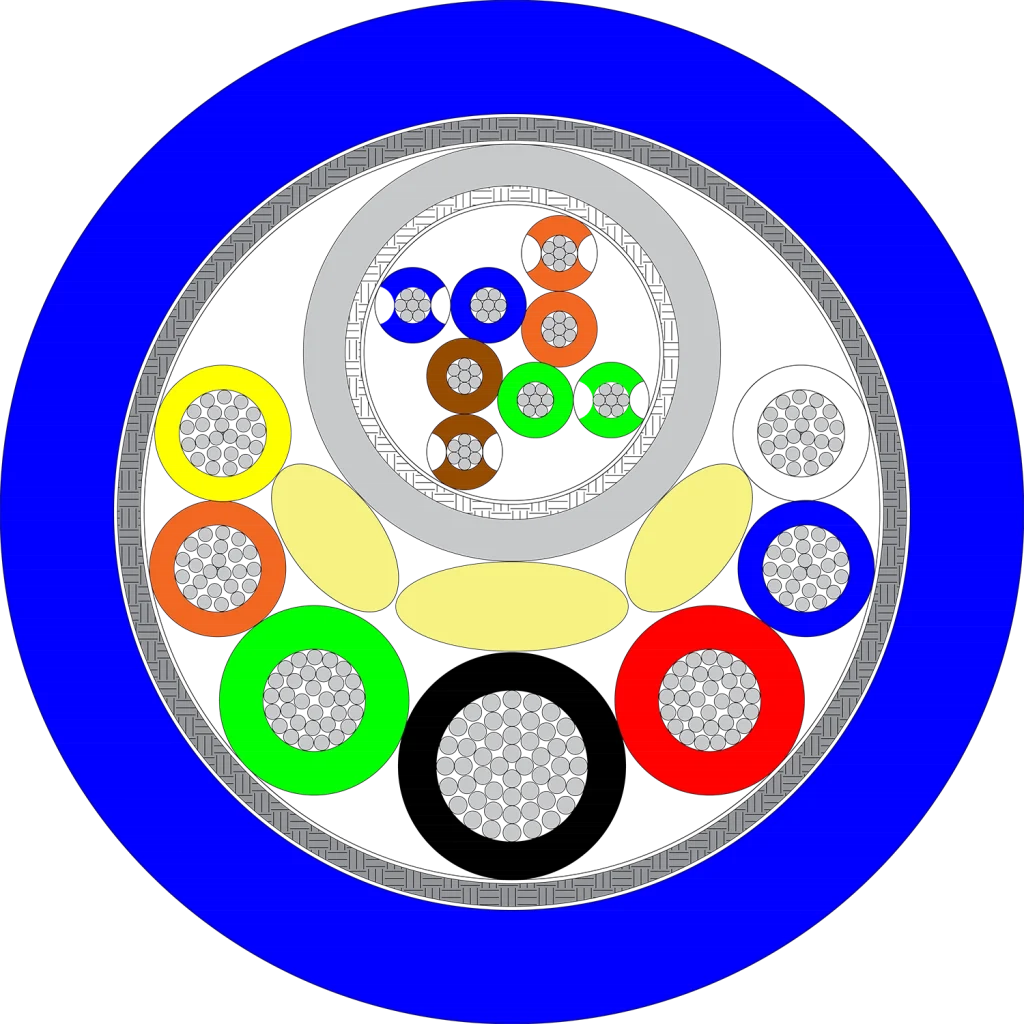

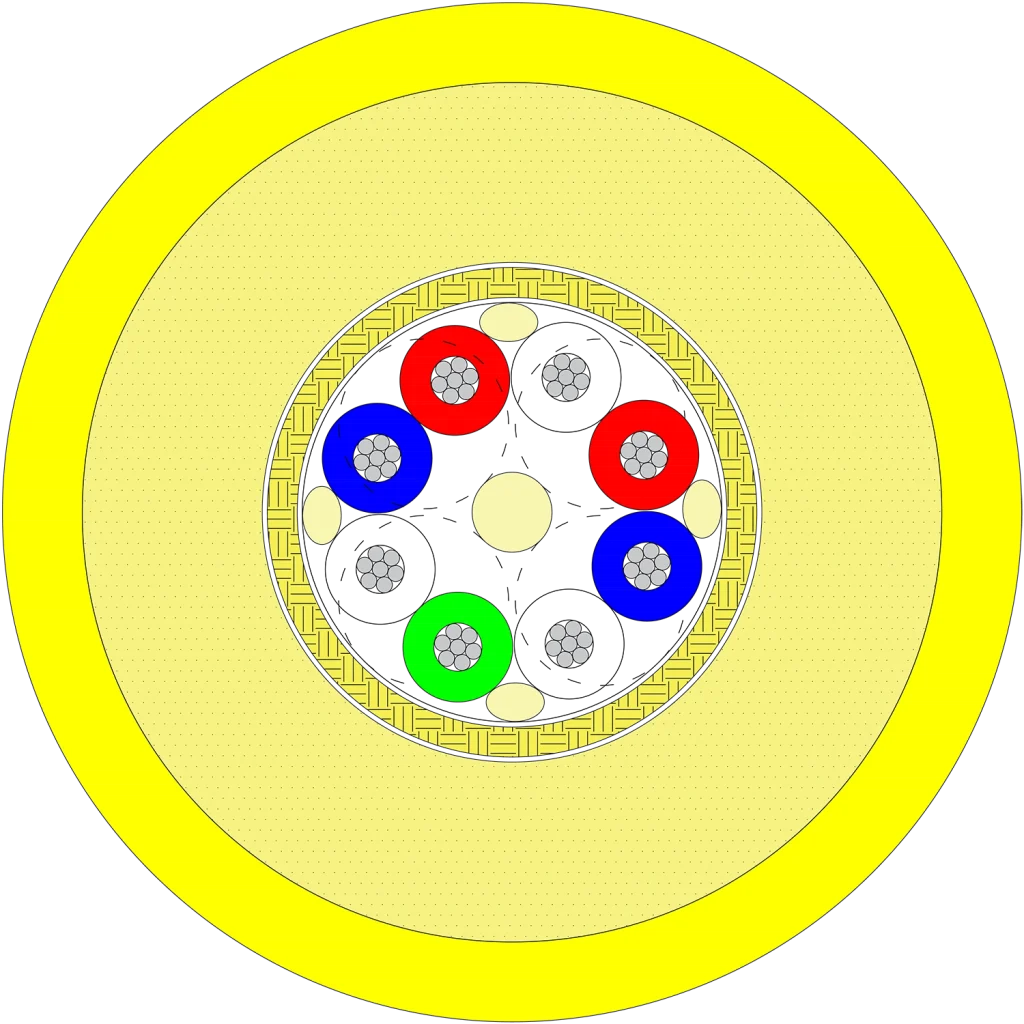

Typical Bespoke Cables

• Turnkey Moulded Cable Assemblies

• Power Cables (Underwater / Subsea)

• High Voltage Cables

• Composite Underwater Communication Cables

• Underwater TV and Video Cables

• Strain Bearing Cables

• Composite Optical / Electrical Cables

• Armoured Cables, Tethers and Umbilicals

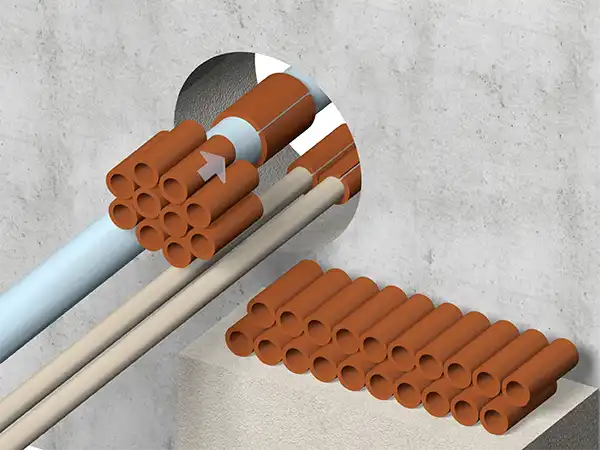

• Laying-Up of Hose, Cable and Strength Member Bundles

• Neutrally Buoyant, Positively Buoyant or Negatively Buoyant Cables and Tethers

• Polyurethane or Polyethylene Jacketed Cables

• Deep Water: 3KM+ Depth Rated Cables

• ROVs: Power, Control and Data Cabling

• FPSO and Support Vessels

• Wind Turbine Farms

• Tidal Energy Farms

• Aquaculture Fish Farms

• Specialist Cable Design Service

• 100 Metres Minimum Order Quantity